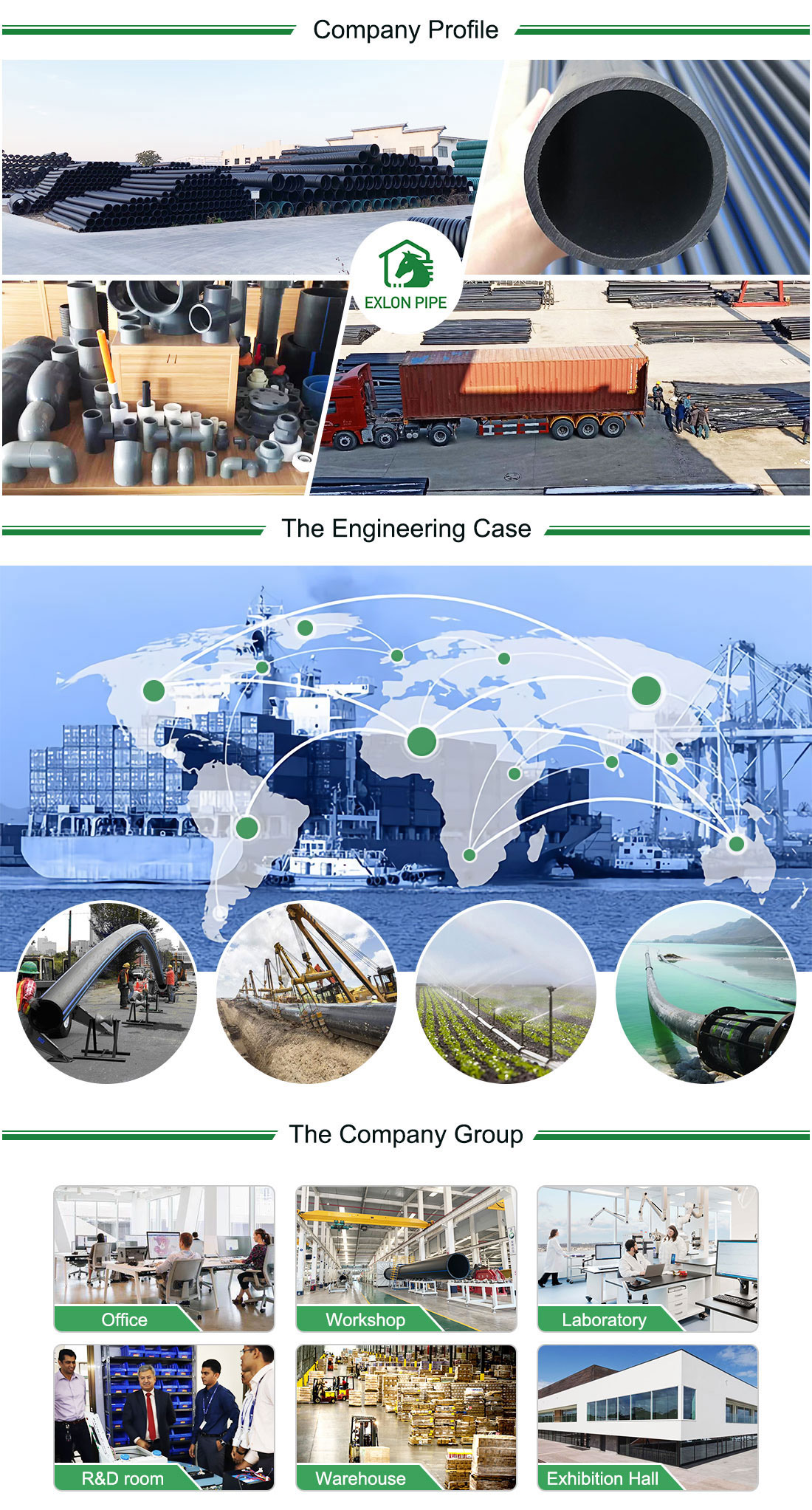

HDPE Silicon-core Pipe

Product: HDPE silicon-core pipe

Material: HDPE

Color: Black,red,blue,yellow,green,purple

Application: Cable protection

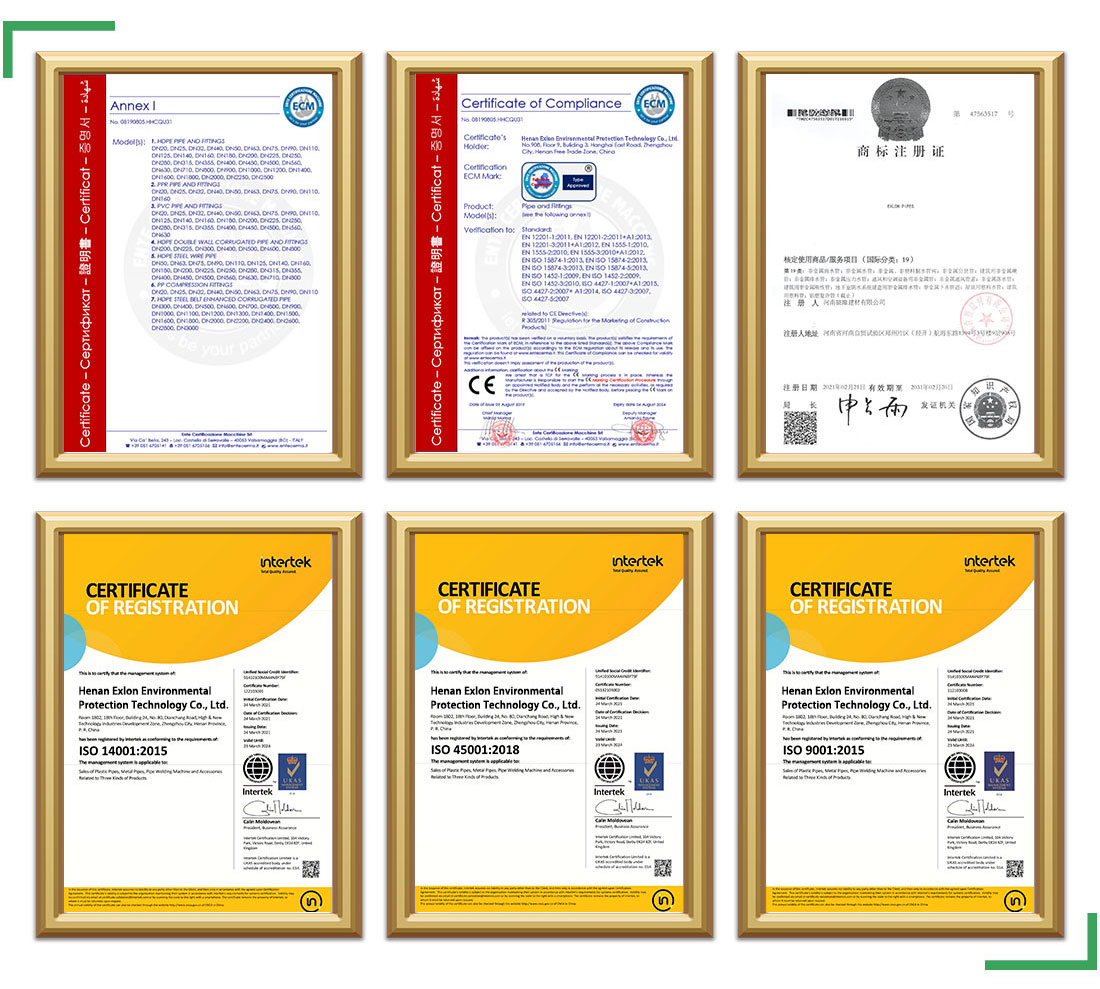

Certification: ISO CE IAF

operating temperature range: -60℃~60℃

Standard: JG/T 496-2004

Product Description

HDPE silicon-core pipes are specially designed to be communication optical(electric) cable protection tubing.The silicon core pipe is produced and shaped through an extruding synchronization with the silicon core material and a low friction coefficient inside the HDPE pipe .Because of that ,the HDPE silicon-core pipe provides excellent covenience for cable laying due to the durability and low friction coefficient inside the lubricating solid tunnel.It is among the most advanced methods for optical cable protection in the world today.

Specification

Specification | OD (mm) | ID (mm) | Tickness (mm) | length (m) | Elasticity | |||||||||

32/26 | 32 | 26 | 2.5 | 1000, 2000, 3000 | Before coiling | After coiling | ||||||||

34/28 | 34 | 28 | 3 | 1000, 2000, 3000 | ≤2 | ≤3 | ||||||||

40/33 | 40 | 33 | 3.5 | 1000, 2000, 3000 | ≤2 | ≤3 | ||||||||

46/38 | 46 | 38 | 4 | 1000, 1500 | ≤2.5 | ≤3.5 | ||||||||

50/42 | 50 | 42 | 4 | 1000, 1500 | ≤3 | ≤5 | ||||||||

60/50 | 60 | 50 | 5 | 1000, 1500 | ≤3 | ≤5 | ||||||||

Application

Optical communication network system of highway, railway,etc.

Features

1. With Silicone solid lubricant in inner wall,which be widely used in optical communication network system of highway, railway,etc.

2. Adopt the mode of multi-machine co-extrusion, silicon core layer is synchronizely embedded in the pipe. It is lubricated and will not be stripped forever.

3. Low friction coefficient of the inner wall . Optical cable (electric cable) can be repeatedly extracted and tensioned in the pipe. By using cable blowing machine, one time blowing length can be 1000 to 2000 meter under normal conditions.

4. Waterproof, damp-proof, can avoid the damage by rodent animals.

5. With great ring stiffness and toughness. its bending radius should not be less than 10 times of the external diameter of the pipe.

6. Aging-resistant, anticorrosion of chemicals, with 50 years service life.

7. Good weather resistant ability, and its suitable temperature scope is from -40°C to 100°C.

8. Convenient in construction. This will save time and the project cost less than 70% of the PVC electronical pipe.

Precautions:

DO ✔:

Keep the pipes and fittings away from sharp objects, heat sources, and toxic and corrosive materials. Before you need to use pipes

and fittings, keep the protective packaging intact. Prevent dust or other materials from entering the pipe. Untie the pipe and

allow it to heat up in the sun before burial.

DON”T ❌:

Throw pipe from delivery vehicles. Place pipeand fittings incontact withlubricating oil,gasoline,solvents,or other aggressive

materials. Heat pipe with an open flame.

Certifications

FAQ

Q: What is your MOQ?

Order amount>=1,000USD, 30% T/T in advance, balance before shipment.

Order amount>20,000USD, 30% T/T in advance, balance L/C at sight acceptable.

Order amount>100,000USD, 100% L/C at sight acceptable.