HDPE Gas Pipe

HDPE Gas Pipe

HDPE Black Pipe For Gas

Specification: 20mm-630mm

Thickness: 2-57.2mm

Pressure: PN0.6-1.6MPa (PN6-16 bar), SDR11-26

Length: 5.8m/11.9m or as required

Standard: GB/T13663-2000, ISO4427-1:2007

Material: PE, Polyethylene

Color: Black with yellow stripe

Product Description

HDPE black pipe for gas is manufactured from superior PE 4710 resin material for greater performance and an extended life expectancy.

Specification

Nominal Diameter DN(mm) | Thickness(mm) | |

SDR11 | SDR17.6 | |

20 | 2.3 | 2.3 |

25 | 2.3 | 2.3 |

32 | 3 | 2.3 |

40 | 3.7 | 2.3 |

50 | 4.6 | 2.9 |

63 | 5.8 | 3.6 |

75 | 6.8 | 4.3 |

90 | 8.2 | 5.2 |

110 | 10 | 6.3 |

160 | 14.6 | 9.1 |

200 | 18.2 | 11.4 |

250 | 22.7 | 14.2 |

315 | 28.6 | 17.9 |

400 | 36.3 | 22.7 |

500 | 45.4 | 28.4 |

630 | 57.2 | 35.7 |

Application

It may be installed by heat fusion or mechanical fittings. The product’s physical properties make it applicable to open-trench and slip-lining installations.

Benefits

HDPE black pipe for gas is manufactured from superior PE 4710 resin material for greater performance and an extended life expectancy.

1. Its butt-fused joints eliminate potential leak points, common at 20 feet with ductile iron pipe, for a zero leak rate.

2. Highly resistant to corrosion and weather, recent studies conclude it will last at least 50 years.

3. Its light weight and flexibility make it easy to install, eliminate the need for fittings required with directional changes, and make it highly suitable for use in earthquake-prone areas.

4. Its high-strength walls give it the highest PE pressure rating, outstanding resistance to SCG and increased resistance to rapid crack propagation.

5. The increased working stress rating of high-performance PE 4710 resin material allows use of a larger inside diameter (thinner wall) for a given operating pressure, making it a superior choice over steel or ductile iron pipe, especially for the large-diameter pipe sizes.

Precautions:

DO ✔:

Keep the pipes and fittings away from sharp objects, heat sources, and toxic and corrosive materials. Before you need to use pipes

and fittings, keep the protective packaging intact. Prevent dust or other materials from entering the pipe. Untie the pipe and

allow it to heat up in the sun before burial.

DON”T ❌:

Throw pipe from delivery vehicles. Place pipeand fittings incontact withlubricating oil,gasoline,solvents,or other aggressive

materials. Heat pipe with an open flame.

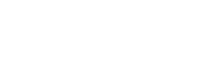

Company Profile

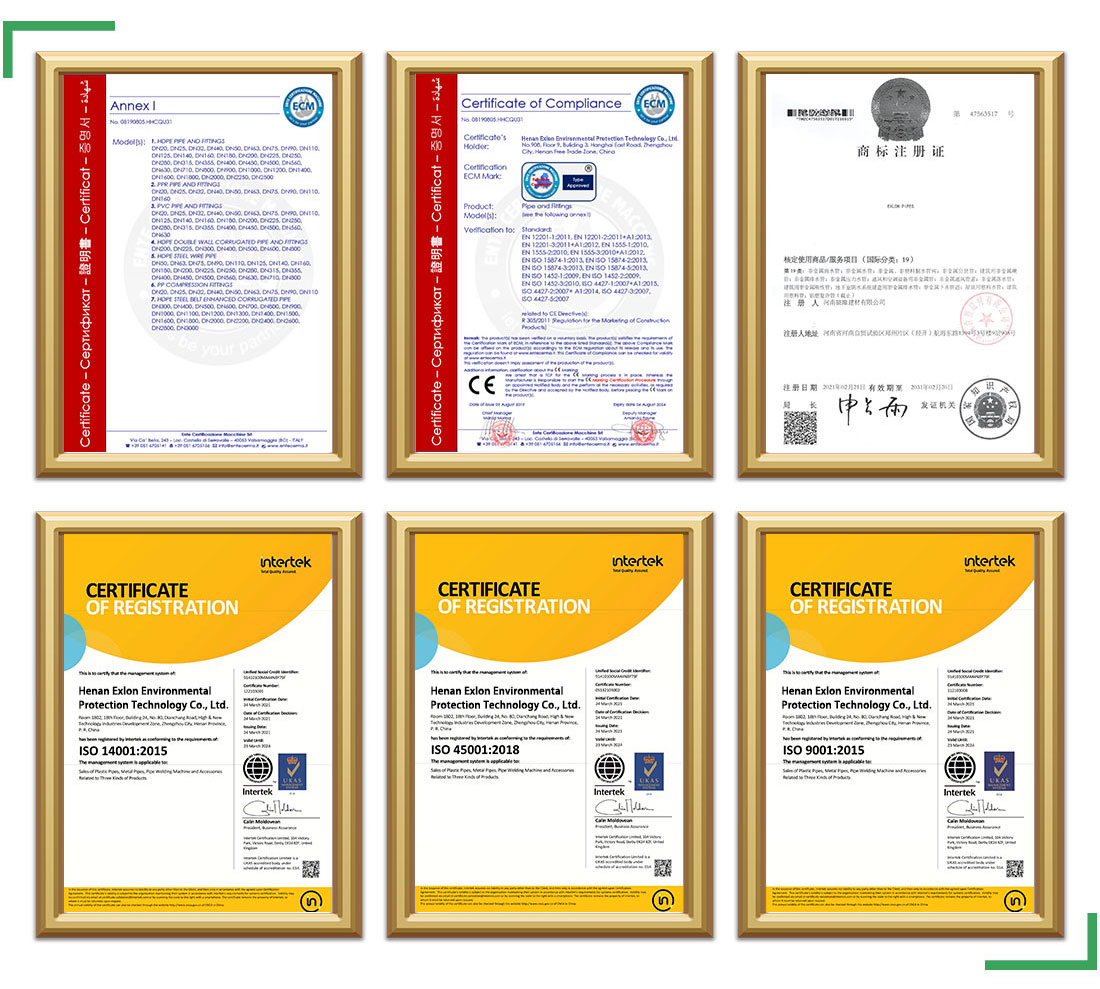

Certifications

FAQ

Q: What is your MOQ?

Order amount>=1,000USD, 30% T/T in advance, balance before shipment.

Order amount>20,000USD, 30% T/T in advance, balance L/C at sight acceptable.

Order amount>100,000USD, 100% L/C at sight acceptable.