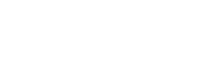

PE Steel Framed Pipe

Thickness: 5.5mm~23.0mm

Specification: 50mm~630mm

Length: 5.8m, 11.8m

Standard: ISO4427, EN, DIN, AS, ASTM

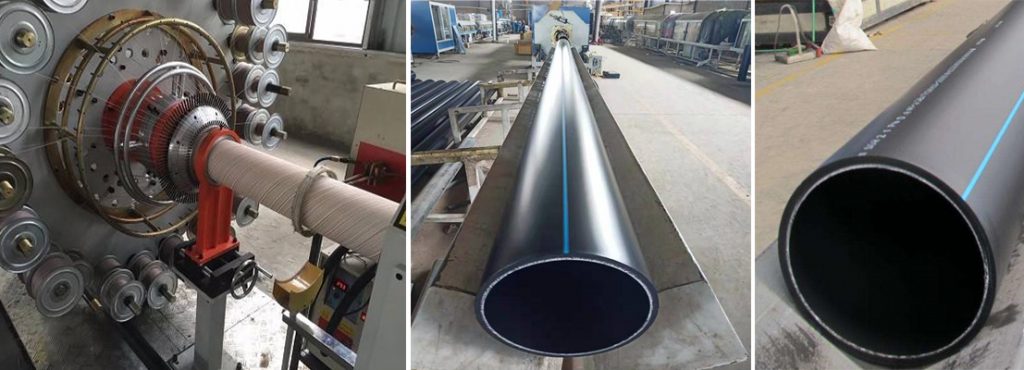

Color: Black, customized

Raw material: PE100

Working pressure: PN10-PN16

Certificate: ISO4427,ISO9001,CE

Working Temperature: – 40℃ to 60℃

Product Description

This products series is a new style of low,medium,and high pressure resistant composite pipes,taking high strength adhesive coated steel wires as the reinforcement between inner and outside composite thermoplastics. Hygienic implementation standards GB/T17219 《 Safety evaluation index of drinking water distribution and distribution equipment and protective materials 》, the products standards conforms with CJ/T189-2007.

Specification

ring stiffness | SN16 | SN12.5 | SN10 | SN8 | SN6 |

Pressure rating | SDR11 | SDR13.6 | SDR17 | SDR21 | SDR26 |

outer diameter(mm) | thickness | thickness | thickness | thickness | thickness |

20 | 2.3 | ||||

25 | 2.3 | ||||

32 | 3 | ||||

40 | 3.7 | ||||

50 | 4.6 | ||||

63 | 5.8 | 4.7 | |||

75 | 6.8 | 5.6 | 4.5 | ||

90 | 8.2 | 6.7 | 5.4 | 4.3 | |

110 | 10 | 8.1 | 6.6 | 5.3 | 4.2 |

125 | 11.4 | 9.2 | 7.4 | 6 | 4.8 |

140 | 12.7 | 10.3 | 8.3 | 6.7 | 5.4 |

160 | 14.6 | 11.8 | 9.5 | 7.7 | 6.2 |

180 | 16.4 | 13.3 | 10.7 | 8.6 | 6.9 |

200 | 18.2 | 14.7 | 11.9 | 9.6 | 7.7 |

225 | 20.5 | 16.6 | 13.4 | 10.8 | 8.6 |

250 | 22.7 | 18.4 | 14.8 | 11.9 | 9.6 |

280 | 25.4 | 20.6 | 16.6 | 13.4 | 10.7 |

315 | 28.6 | 23.2 | 18.7 | 15 | 12.1 |

355 | 32.2 | 26.1 | 21.1 | 16.9 | 13.6 |

400 | 36.3 | 29.4 | 23.7 | 19.1 | 15.3 |

450 | 40 | 33.1 | 26.7 | 21.5 | 17.2 |

500 | 45.4 | 36.8 | 29.7 | 23.9 | 19.1 |

560 | 50.8 | 41.2 | 33.2 | 26.7 | 21.4 |

630 | 57.2 | 46.3 | 37.4 | 30 | 24.4 |

710 | 52.2 | 42.1 | 33 | 27.2 | |

800 | 58.8 | 47.4 | 38 | 30.6 | |

900 | 53.3 | 42.9 | 34.4 | ||

1000 | 59.3 | 47.7 | 38.2 | ||

1200 | 57.2 | 45.9 |

Features

High strength, rigidity, impact resistance, double face corrosion, use temperature increase, heat conduction coefficient is decreased, the use of the outer wall not need heat preservation in the winter, summer is used without dew. Smooth inner wall, noscaling, the head loss is 30% lower than the steel pipe. Light weight, easy to transport. Low cost and non-toxic health, it is the best substitute for galvanized pipe.

Precautions:

DO ✔:

Keep the pipes and fittings away from sharp objects, heat sources, and toxic and corrosive materials. Before you need to use pipes

and fittings, keep the protective packaging intact. Prevent dust or other materials from entering the pipe. Untie the pipe and

allow it to heat up in the sun before burial.

DON”T ❌:

Throw pipe from delivery vehicles. Place pipeand fittings incontact withlubricating oil,gasoline,solvents,or other aggressive

materials. Heat pipe with an open flame.

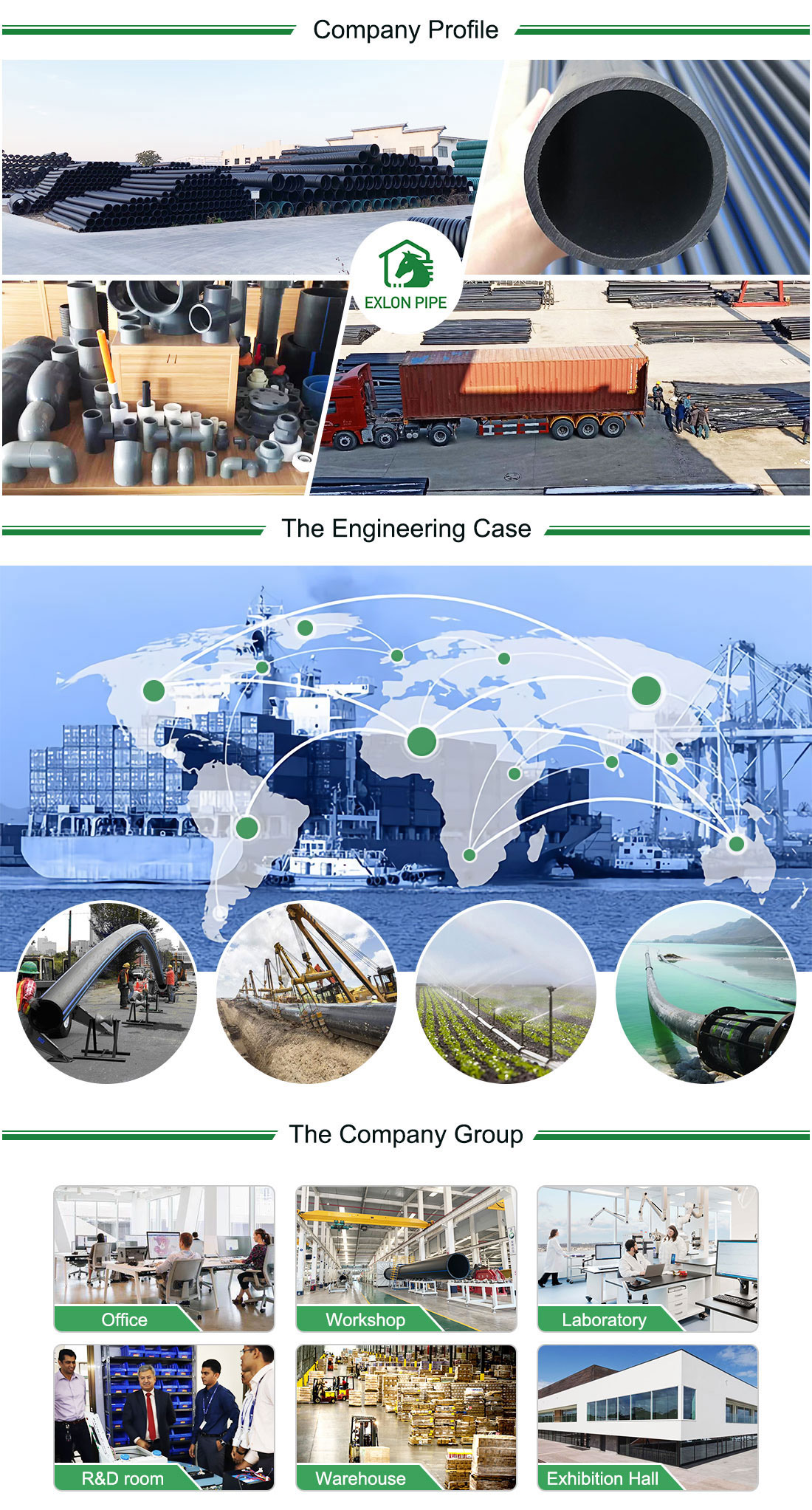

Company Profile

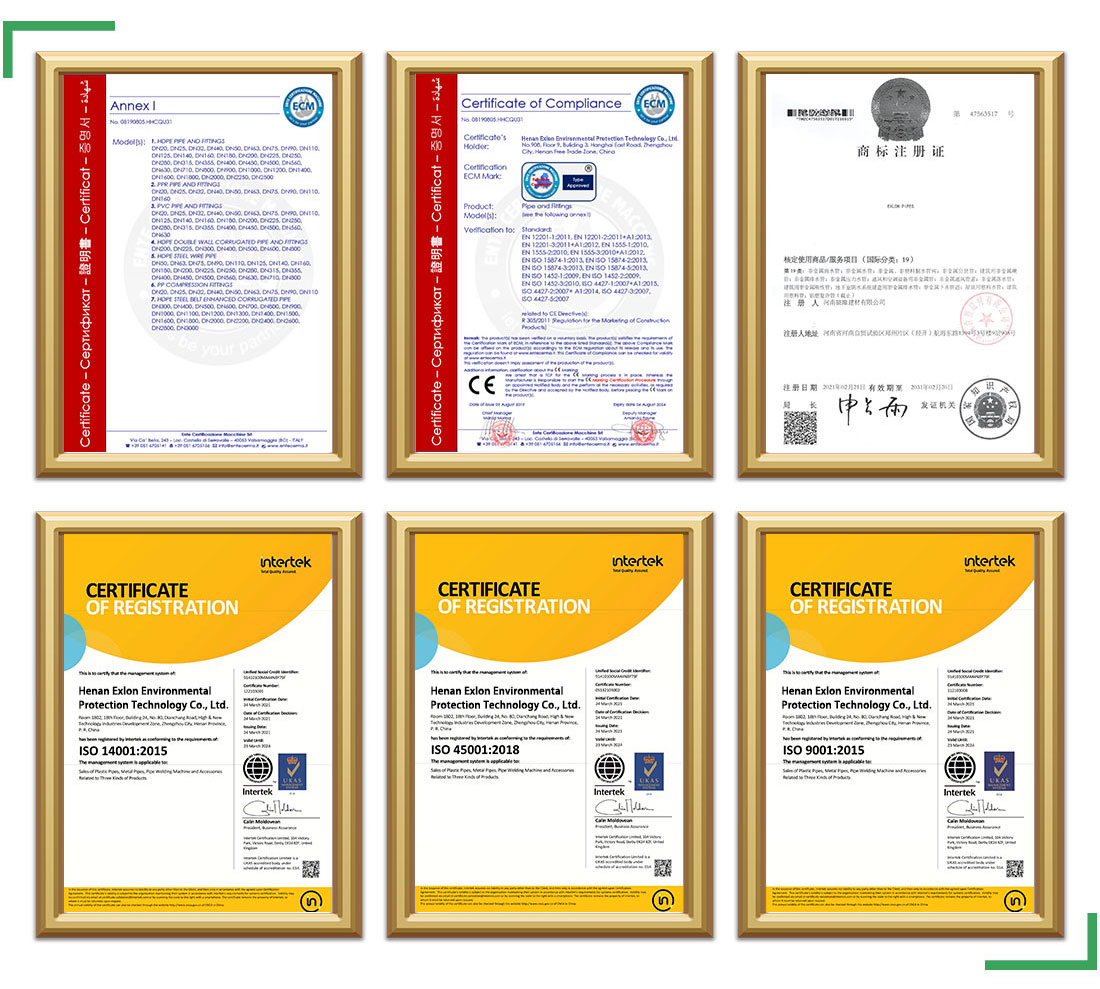

Certifications

FAQ

Q: What is your MOQ?

Order amount>=1,000USD, 30% T/T in advance, balance before shipment.

Order amount>20,000USD, 30% T/T in advance, balance L/C at sight acceptable.

Order amount>100,000USD, 100% L/C at sight acceptable.