HDPE Gas Pipe

- Water supply field

- Agricultural irrigation field

- Mining field

- Construction sector

Complete control over products allows us to ensure our customers receive the best quality prices and service.

SEND EMAIL

PHYSICAL AND MECHANICAL PROPERTIES

| PHYSICAL INDEX | STANDARD | UNIT | PE 100 | |

| Density | DIN 53479 ISO 1183 | g/cm3 | 0.96 | |

| Melt index MFR 190/5 MFR 190/21.6 MFR 230/5 | Code T Code V Code V | ISO 1133 | g/10 min | 0.45 6.6 |

| Short term modulus of elasticity Long term modulus of elasticity(50years) | ISO 178 | N/mm2 | 1200 170 | |

| Yield stress | DIN 53495 | N/mm2 | 25 | |

| Tensile stress | DIN 53495 | N/mm2 | 38 | |

| Elongation at break | ISO 2039 | % | >600 | |

| Ball indentation hardness | ISO 2039 | N/mm2 | 46 | |

| Linear expansion coefficient | DIN 53752 | 1/oC | >600 | |

| Color | - | - | Black/yellow |

SPECIFICATIONS

| NOMINAL SIZE (DN/ID) | MINIMUM AVERAGE INNER DIAMETER (DIM,MIN) | MINIMUM WALL THICKNESS (STYLE B, E4,MIN) | NOMINAL SIZE (DN/ID) | MINIMUM AVERAGE INNER DIAMETER (DIM,MIN) | MINIMUM WALL THICKNESS (STYLE B, E4,MIN) |

| 200 | 195 | 1.5 | 1600 | 1585 | 5 |

| 300 | 294 | 2 | 1700 | 1685 | 5 |

| 400 | 392 | 2.5 | 1800 | 1785 | 5 |

| 500 | 490 | 3 | 1900 | 1885 | 5 |

| 600 | 588 | 3.5 | 2000 | 1985 | 6 |

| 700 | 673 | 4 | 2100 | 2085 | 6 |

| 800 | 785 | 4.5 | 2200 | 2185 | 7 |

| 900 | 885 | 5 | 2300 | 2285 | 8 |

| 1000 | 985 | 5 | 2400 | 2385 | 9 |

| 1100 | 1085 | 5 | 2500 | 2485 | 10 |

| 1200 | 1185 | 5 | 2600 | 2585 | 10 |

| 1300 | 1285 | 5 | 2800 | 2785 | 12 |

| 1400 | 1385 | 5 | 3000 | 2985 | 14 |

| 1500 | 1485 | 5 |

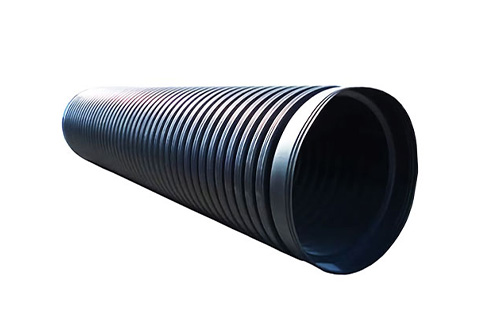

It is a high-density polyethylene pipe featuring a smooth inner wall and a spiral-reinforced outer structure. Often called Krah Pipe or Type B Structural Wall Pipe, it provides high ring stiffness (SN8–SN16) and integrated electro-fusion joints, making it ideal for heavy-duty underground municipal sewage and drainage systems.

The pipe is manufactured using a hot-winding process. High-density polyethylene resin and polypropylene reinforcement profiles are wound onto a heated, rotating steel mandrel in a molten state. This synchronized winding ensures layers fuse seamlessly without internal stress, creating a robust, homogeneous structure with customized wall thicknesses and integrated sockets.

Backed by 25 years and 116 production lines, EXLON PIPE ensures disciplined quality and stable supply reliability.

CE/ISO compliant

Tailored designs

Volume discounts

Full fittings range

Stable supply chain

Full-Process Fast Response

Get In Touch

We support engineering contractors and project procurement teams with HDPE & PVC pipe solutions across Africa, the Middle East and Latin America. Let us know your project requirements and we will respond promptly.

Get In Touch

We support engineering contractors and project procurement teams with HDPE & PVC pipe solutions across Africa, the Middle East and Latin America. Let us know your project requirements and we will respond promptly.