Exlon’s Mission: Connecting Every Critical Project with Reliable Piping Solutions

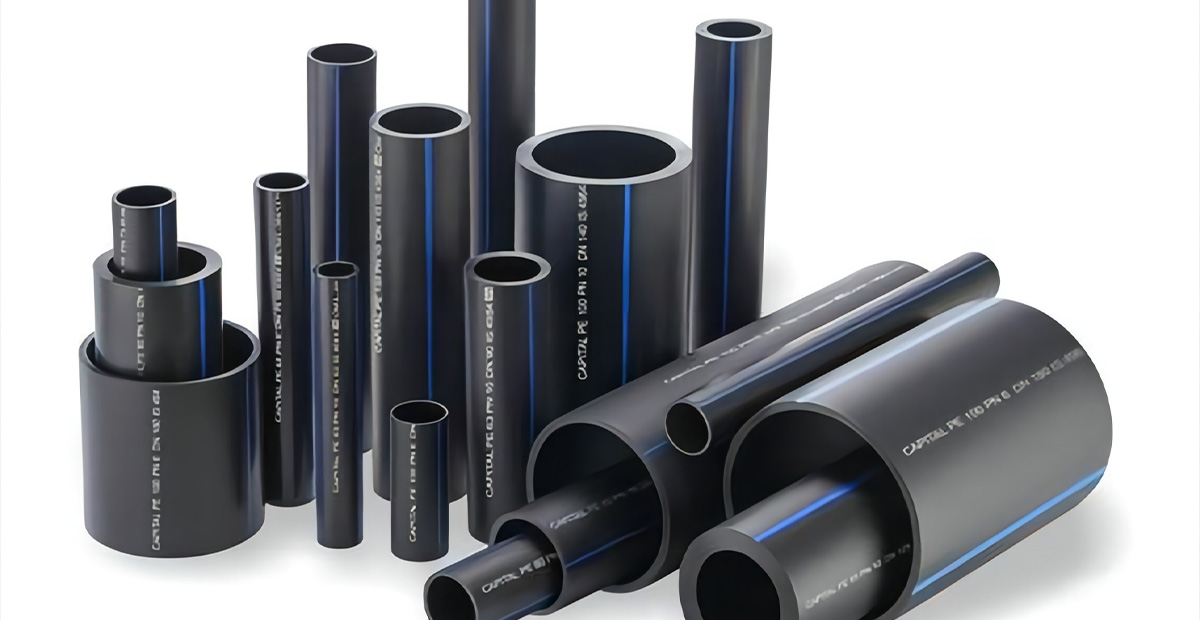

What Is Exlon Pipe?

Exlon Pipe is a premier Chinese pipe exporter and global supplier.Our product range primarily focuses on advanced thermoplastic materials, including HDPE (High-Density Polyethylene), PE, and PVC piping solutions. Unlike traditional metal systems, these materials are designed to resist corrosion, handle chemical exposure, and withstand ground movement. Whether it is for municipal water supply, industrial fluid transport, or complex drainage systems, Exlon products serve as the reliable "veins" of modern infrastructure, ensuring essential resources reach their destination without leakage or interruption.

The reason more engineers and project managers are turning to Exlon today is our proven track record in reliability and scale. With 25 years of production experience and 116 advanced production lines, we have evolved into a leading global pipe supplier capable of meeting massive industrial demands while maintaining strict quality control. Since our founding in 2005, we have served over 1,000 clients in more than 100 countries. Whether you are a large-scale construction firm or a regional piping wholesaler, Exlon provides a practical balance of cost-effectiveness and long-term performance, backed by an R&D team that understands the stresses of real-world engineering.

At the heart of our operations is a simple but vital purpose: to provide the "invisible strength" that keeps our world moving. Our mission—“Connecting Every Critical Project with Reliable Piping Solutions”—is our promise that every joint we seal and every meter of pipe we produce contributes to a safer, more sustainable environment. As a trusted pipe factory, our goal is to eliminate the risks associated with infrastructure failure. By delivering world-class piping systems to global markets, Exlon strives to empower local communities and industrial sectors with the infrastructure they need to grow with total confidence.

Why "Reliable Piping" Matters So Much?

Reliable piping isn’t a nice-to-have — it’s a practical necessity for any serious project. Leaks in a pipe network quickly become large maintenance bills: repeated excavation, emergency repairs and lost service create ongoing costs that far exceed initial material savings. Underground lines that corrode or age out prematurely, PVC runs that fail under pressure or impact, and metal pipes that rust or reach end-of-life early all force unplanned downtime and replacement. In extreme climates, pipes that crack in heat or freeze in cold turn routine operation into a risk. Those common field problems erode budgets, delay schedules, and leave owners and engineers managing crises instead of projects.

That’s why projects need a long-term, trustworthy piping system rather than a lowest-price component. Stable, corrosion-resistant materials, proven jointing methods and predictable performance under ground movement and temperature swings reduce lifecycle cost and keep construction and operations on schedule. Contractors and procurement teams choose suppliers and manufacturers who offer tested systems and technical support because the value shows up in fewer callbacks, lower operating expense and smoother project delivery. In short: the right pipe keeps water, waste and industrial fluids moving — reliably — and transforms the pipe network from a recurring liability into a dependable part of infrastructure.

How Exlon Solves These Industry Challenges?

To move from identifying industry pain points to delivering results, Exlon leverages decades of manufacturing expertise to provide high-performance piping systems. As a specialized pipe manufacturer and global supplier, we don't just sell products; we engineer solutions that specifically target the vulnerabilities of traditional infrastructure.

- Superior Material Grades (PE100): We utilize high-quality PE100 raw materials, ensuring our pipes have the highest strength-to-density ratio. This results in higher durability and a 50-year design life, significantly reducing the need for future replacements.

- Total Corrosion & Chemical Resistance: Unlike metal alternatives, Exlon pipes are naturally resistant to chemicals and corrosion. This makes them the ideal choice for harsh industrial fluids and aggressive soil conditions without the need for expensive protective coatings.

- Seismic & Geological Flexibility: Our pipes offer exceptional flexibility and impact resistance. This "forgiving" nature allows the piping to bend without breaking, making it perfectly suitable for underground and harsh environments, including seismic zones and areas with shifting or uneven terrain.

- Leak-Free Jointing Methods: By utilizing advanced butt fusion and electrofusion welding, we create a monolithic system where the joints are as strong as the pipe itself. These leak-free jointing methods eliminate the most common cause of system failure and environmental contamination.

- Streamlined Installation: Because our materials are lightweight compared to steel or concrete, they allow for easier handling and fast installation. This efficiency directly translates to lower labor and machinery costs, making Exlon cost-effective for long-term projects.

- 50-Year Design Life: By focusing on anti-aging properties and UV resistance, our piping systems are built for a service life exceeding 50 years. This significantly reduces the "Total Cost of Ownership" by minimizing the need for future replacements.

By focusing on these practical advantages, Exlon helps engineers and contractors move away from high-maintenance "quick fixes" and toward a permanent, reliable infrastructure. Whether you are dealing with a municipal water upgrade or a complex industrial site, our goal is to ensure your piping system remains the most reliable part of the project.

The Exlon Pipe System and Its Role in Critical Projects

Exlon delivers more than individual pipes — we supply a complete, system-level solution that covers material, fittings, welding equipment and installation guidance. Our product family spans give-water pipelines, drainage and wastewater systems, industrial process lines, agricultural irrigation networks, and protective conduits for power and communications. Each element is engineered to work together: pipes formulated for strength and chemical resistance, matched electrofusion and butt-fusion fittings that create monolithic joints, and field-ready welding tools and technical support so system performance is predictable from day one.

In extreme environments, that system approach matters. For high-temperature or high-pressure industrial lines and corrosive process fluids, Exlon’s high-grade PE formulations and composite options keep mechanical properties stable and resist chemical attack, reducing embrittlement and loss of service life. In deserts or polar conditions our flexible materials tolerate thermal cycling and ground movement without cracking. Because joints are fused rather than mechanically clamped, the number of potential leak points is dramatically lower — a direct benefit for projects where downtime or contamination is unacceptable.

Exlon piping also plays a quiet but vital role in precision and protection. For electronic and automation installations we supply conduit systems that offer excellent electrical insulation and moisture protection, safeguarding control cables and sensitive circuits from chemical exposure, abrasion and water ingress. The same protective capability is crucial in smart-city deployments where fiber, power and instrument lines must remain serviceable for decades with minimal intervention.

On the public-interest side, Exlon systems help reduce environmental risk and operating cost. In water treatment and energy transport projects, durable materials and leak-free jointing decrease loss, lower contamination risk and minimize emergency excavations that disturb communities and ecosystems. For municipal infrastructure, industrial plants, agriculture and underground utilities alike, Exlon’s integrated solutions are built to lower lifecycle cost, reduce maintenance events and keep critical systems running reliably. In short, by offering coordinated products and support rather than isolated parts, Exlon turns piping from a recurring headache into a dependable foundation for the projects that matter most.

The Persistence Behind Exlon Pipe Quality

At Exlon, quality starts with standards and shows up in every process. Our production follows international benchmarks such as ISO 4427 for polyethylene pressure piping and ISO 9001 for quality management. On the shop floor, intelligent production lines continuously monitor extrusion parameters, wall thickness and material consistency to ensure each pipe meets specification. Incoming raw materials are inspected, in-process checks are logged, and finished products undergo pressure, impact and dimensional testing before release — a strict quality control routine designed to prevent surprises in the field.

Behind that manufacturing rigor is an experienced R&D and technical team that develops material formulations, validates jointing methods and keeps improvement projects moving. We protect innovations with patents and maintain a documented traceability system so customers can verify batch performance when needed. For project owners and contractors this means Exlon delivers not only certified products but documented, repeatable performance. Reliable is not a slogan — it is the result of controlling every step from raw material to finished pipe.

Exlon pipe Sustainability & Global Vision

Exlon’s mission extends beyond providing strong and reliable piping — it also includes building a more sustainable future for global infrastructure. By using cleaner, recyclable PE materials and designing systems that significantly reduce leakage rates, Exlon helps conserve water and energy in regions where every drop and every kilowatt matters. This focus on efficiency allows utilities and industries to operate with lower environmental impact over the long term.

Looking ahead, Exlon continues to develop higher-grade PE materials and more resilient jointing technologies to support the next generation of critical projects. Our products are already used in international water networks, industrial facilities, and rural development programs, offering durable solutions for both developed and emerging markets. Whether reinforcing major infrastructure or helping build reliable systems in developing regions, Exlon is committed to delivering piping solutions that support sustainable growth and benefit communities worldwide.

Why Choose Exlon? The Foundation of Our Advantage

With over 20 years of manufacturing experience, we have refined our production to a science. We understand the nuances of thermoplastic engineering, allowing us to offer a full range of HDPE and PVC pipe systems that meet the diverse needs of municipal, industrial, and agricultural sectors. Whether you require standard dimensions or specialized OEM/ODM production, our 116 production lines provide the flexibility to customize product designs, logos, and packaging to align perfectly with your project requirements.

Quality Without Compromise Reliability is our baseline. We operate an in-house quality testing lab where every batch undergoes rigorous checks for pressure resistance, material density, and durability. We never supply substandard products; all our pipes and fittings are certified by international bodies including CE, ISO, SGS, and CNAS. This ensures that when our pipes are installed in your project—whether in a seismic zone or a high-temperature industrial plant—they perform consistently for decades.

Commercial Efficiency & Global Reach We know that in construction, time is money. Our stable production capacity allows for fast delivery on bulk orders, supported by a proactive logistics network that ensures on-time delivery across international borders. We maintain transparent and competitive pricing, providing detailed cost breakdowns and volume discounts so you can plan your budget with total confidence.

Your Long-Term Partnership Choice Beyond the sale, Exlon provides comprehensive support. From professional technical consultations to dedicated after-sales service and order tracking, we act as an extension of your team. We don't just want to be your supplier for one project; we aim to be your long-term partner in building resilient infrastructure worldwide.

If you are planning a new project or upgrading an existing pipeline system, our team is ready to support you with reliable products and expert guidance.

Contact us for technical datasheets, price lists, and customized solutions for your project.